Why Dry Ice Blasting Is the Future of Industrial Cleaning

Why Dry Ice Blasting Is the Future of Industrial Cleaning

Industrial cleaning has long relied on methods like sandblasting, water pressure cleaning, and chemical treatments. While these techniques can be effective, they often come with trade-offs such as surface damage, waste generation, or health and safety risks. Dry ice blasting, a more recent development, is changing how industries approach maintenance and cleaning.

Using compressed air to propel dry ice pellets at high speed, this method offers a cleaner, faster, and more environmentally responsible way to remove dirt, oil, paint, and other contaminants from equipment and surfaces. Its gaining widespread adoption across sectors like manufacturing, energy, food processing, and restoration.

What Is Dry Ice Blasting?

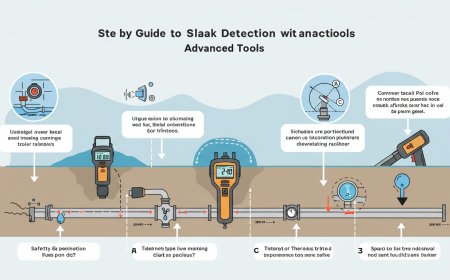

Dry ice blasting involves shooting solid carbon dioxide pellets at surfaces using pressurized air. These pellets are extremely cold, at about ?78.5C (?109.3F), and they sublimate on contactturning from solid directly into gas.

The cleaning effect is achieved through three combined actions. The physical force of the pellets knocks debris loose. The cold temperature causes surface contaminants to shrink and lose adhesion. Finally, when the dry ice pellets sublimate, the rapid gas expansion helps lift remaining material from the surface.

Unlike abrasive methods, dry ice blasting doesnt damage the underlying material, and since the pellets vaporize, theres no secondary waste to dispose of.

Cleaner and Safer Than Traditional Methods

One of the biggest advantages of dry ice blasting is that it leaves no residue. Traditional methods like sandblasting or soda blasting leave behind grit or slurry that must be cleaned up after the process. Water-based methods create runoff, which can be problematic in sensitive or electrical environments. Chemical cleaning introduces toxins and requires careful handling, ventilation, and disposal.

Dry ice blasting avoids all of these issues. Its non-toxic, non-abrasive, and dry. It doesnt involve water or harsh substances, making it ideal for use in food-grade facilities or around sensitive machinery.

Reduced Downtime and Higher Efficiency

Because dry ice blasting can often be performed without dismantling machinery, it reduces downtime dramatically. Operators can clean production equipment in place, which saves both time and labor.

For example, in the food and beverage industry, entire production lines can be cleaned without full shutdowns. In automotive manufacturing, molds and parts can be cleaned between runs without waiting for them to cool or be disassembled.

This in-place cleaning capability is a major reason why industries are shifting toward dry ice blastingit improves operational efficiency while maintaining high standards of cleanliness.

Versatile Across Industries

Dry ice blasting is highly adaptable and used in many sectors. In food processing, it removes residues like baked-on oils, sugars, or powders from ovens and conveyors. Because it's dry and chemical-free, it complies with strict hygiene standards.

In the power and energy industries, its used to clean electrical insulators, transformers, and turbines without the risk of moisture damage. In aerospace and automotive fields, it removes paint, sealants, and adhesives without affecting surface integrity.

Even in historic preservation or fire restoration, dry ice blasting can gently remove smoke damage, mold, or graffiti from wood, brick, and metal without harming the original surface.

Environmentally Responsible Cleaning

Environmental impact is a growing concern for companies worldwide. Dry ice blasting aligns well with green initiatives. The CO? used in the process is usually collected as a byproduct from industrial sources and reused, meaning it doesnt contribute to net carbon emissions.

Because there are no chemicals involved, theres no risk of contaminating soil or water. Facilities that use this method often see a reduction in hazardous waste and the costs associated with its disposal.

In addition, because its a dry method, theres no need for drying time, drainage systems, or chemical neutralization procedures.

Important Considerations for Use

While dry ice blasting offers many benefits, its important to follow proper safety protocols. Operators should wear protective gear and ensure that work areas are well-ventilated. Since CO? is heavier than air, it can displace oxygen in confined spaces if ventilation is inadequate.

The equipment for dry ice blasting can be more expensive upfront than conventional tools. However, many organizations find that the long-term savings in labor, reduced downtime, and lower waste management costs make it a worthwhile investment.

Conclusion

Dry ice blasting is quickly becoming a preferred cleaning solution for industrial environments that demand safety, efficiency, and environmental responsibility. Its non-abrasive, residue-free process makes it suitable for a wide range of applications, from heavy equipment maintenance to delicate restoration work.

As industries continue to prioritize sustainability and operational efficiency, dry ice blasting stands out as a future-focused method that delivers powerful cleaning without compromise.